What are our options and manufacturing lead times?

Fast-track sizes, custom sizes, options – what are the manufacturing times?

Balcony systems news | Glass Balustrades | Juliette Balconies | Curved Glass Balustrades

Self Cleaning Glass | Composite Decking | Partner Outlet | Situations Vacant

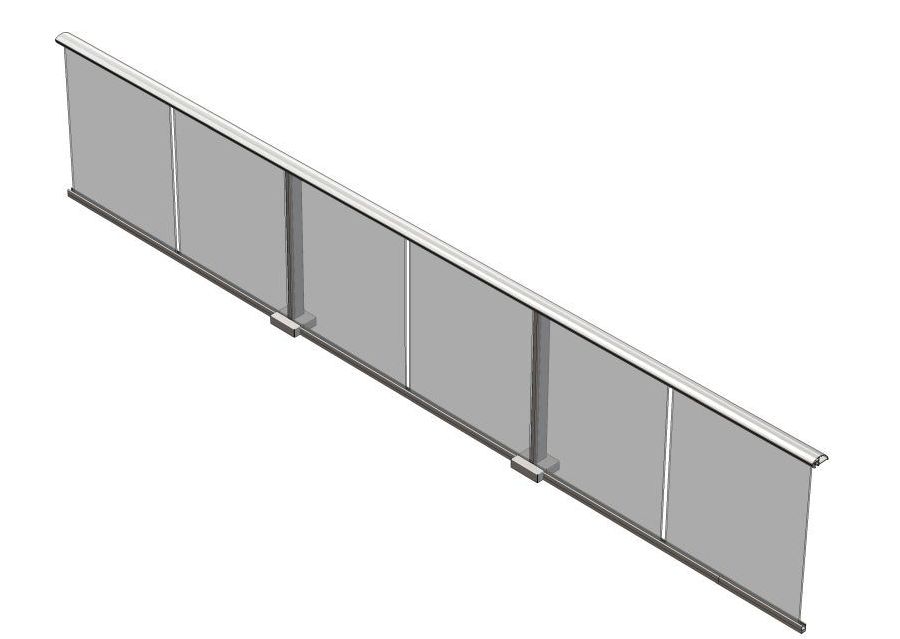

Supporting balustrades without posts – how is it possible?

Our unique Hybrid® system enables long runs of balustrading with few – or no – upright posts. Effi Wolff explains…

Need it in a hurry?

Our “Fast Track” option could be just what you need for a project that needs to be completed in a…

Load More